Color Consistency

You may encounter significant differences in the color of EPDM granules from different batches, which can affect the overall appearance of the final surface, especially in projects with strict color requirements.

FieldsMaster's mission is not only to offer competitively priced products but, more importantly, to provide unparalleled quality. For clients with high expectations for the quality and performance of EPDM granules, we are committed to being your strong support in the pursuit of excellence.

You may encounter significant differences in the color of EPDM granules from different batches, which can affect the overall appearance of the final surface, especially in projects with strict color requirements.

Another common issue faced by installation personnel is a lack of familiarity with the proper installation methods for EPDM surfaces. Without proper knowledge of the installation process, achieving optimal results becomes challenging, leading to potential errors and inefficiencies.

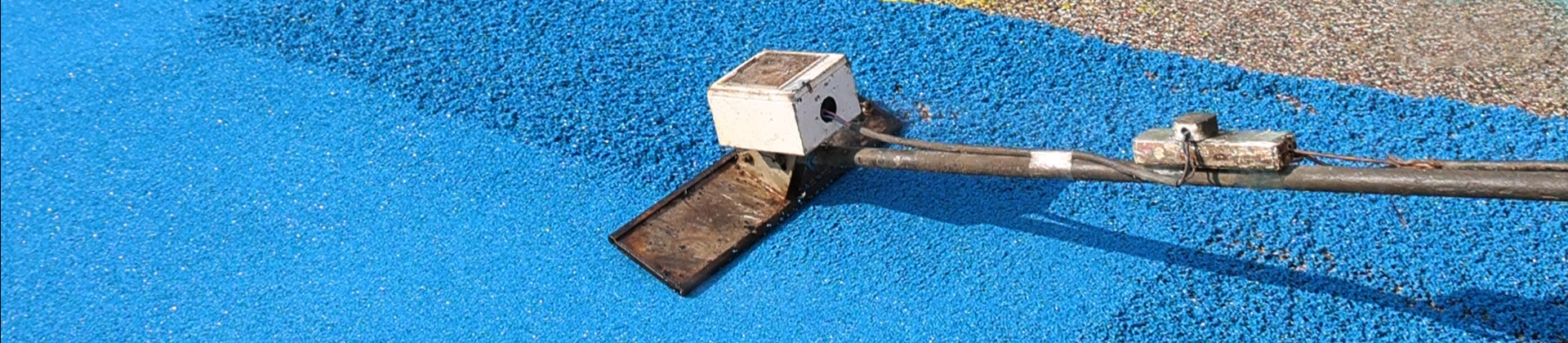

Using the wrong or damaged tools can lead to delays, poor quality work, and safety risks.

Ensure the right tools are available by planning ahead and maintaining them regularly. Implement a tool tracking system and provide worker training on proper tool use.

Delays in material delivery can disrupt construction schedules and lead to project holdups.

Optimize supply chain management by working with reliable suppliers, planning deliveries in advance, and using multiple transport options to minimize delays.

Challenges may arise due to noticeable color variations between different batches of EPDM granules, impacting the overall appearance of the final surface, especially critical in projects with strict color requirements.

The stability of pallet during transportation is another challenge, as collapse may lead to damage to goods and increased costs.

Including customization in terms of color, particle size, polyurethane content, etc.

Technical training, construction guidelines, and guidance

Including raw material procurement, inventory management and transportation, etc.

3D sculptures made of EPDM particles with design and fun, both aesthetic and practical.

Provide QC report to ensure the quality and safety of the project.

Provide a streamlined order processing process and real-time view of order progress through the official website.

We have more than 20 years of experience in R&D and manufacturing EPDM Granules and master industry-leading technology

We have more than 20 years of experience in R&D and manufacturing EPDM Granules and master industry-leading technology

We have more than 20 years of experience in R&D and manufacturing EPDM Granules and master industry-leading technology

It is critical to ensure that the substrate is clean, dry and free of debris before beginning installation. Proper surface preparation is critical for optimal adhesion and longevity of the EPDM surface.

Essential tools for installing EPDM surfaces include mixers, rollers, utility knives, pavers, etc. These tools can be found on our official website.

Preparation steps include thoroughly cleaning the substrate, repairing any irregularities in the surface, and applying a suitable primer or adhesive to enhance the bond between the EPDM surface and the substrate.

Proper adhesion requires an even application of adhesive to the substrate and ensuring that the EPDM rubber granules are pressed firmly into the adhesive layer. The use of a suitable roller can help to achieve an even bond.